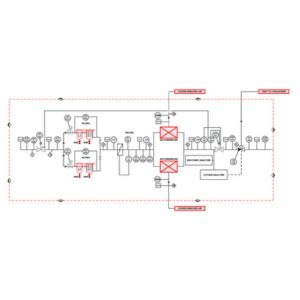

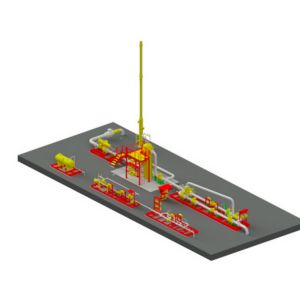

The lean glycol effectively absorbs water from the gas stream, resulting in the formation of rich glycol which undergoes regeneration in the glycol regeneration section. Within this section, the rich glycol releases water, allowing for the removal of dissolved hydrocarbons. The rich glycol, now laden with water and hydrocarbons, undergoes a series of precise steps including flashing to an intermediate pressure, pre-heating in the glycol condenser, and filtration in cartridge and activated carbon filters to ensure optimal performance of the system. The glycol then proceeds to the still column, complete with an integral reboiler where heating occurs via electric, fired gas, or hot oil heater. The glycol stripping column further refines the glycol purity, with the lean glycol ultimately returning to the contactor column for continuous operation. BlissFlow’s Glycol Type Gas Dehydration Units are meticulously designed with a focus on efficiency, reliability, and superior performance, supported by a comprehensive suite of interconnecting piping, valves, steelworks, instrumentation, and control systems. Additional inlet and outlet conditioning facilities, corrosion control systems, and glycol maintenance features are available based on specific project requirements, ensuring a tailored solution for each client’s gas dehydration needs.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.