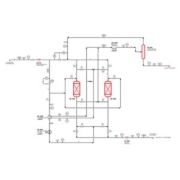

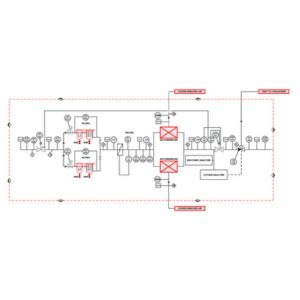

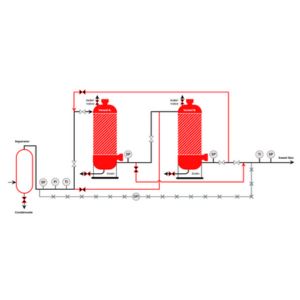

The filtered air then moves on to a heatless pressure swing dryer with two adsorption towers, operating alternately to dry and regenerate. The wet air flows through the adsorbent bed, made of activated alumina with inert spheres at the top and bottom, to remove water to below the required specifications. The regeneration process involves depressurization and counter-current purge, with regulated air vented through a silencer to minimize noise. After re-pressurization, the dry air is passed through 2×100% after-filters to ensure any remaining desiccant fines are removed. Our unit is complete with all necessary components, including piping, valves, steelworks, instrumentation, and control systems, to guarantee a seamless process from start to finish.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.