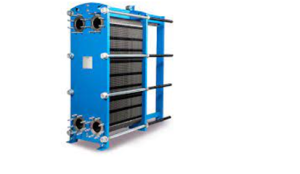

PLATE HEAT EXCHANGER:

A plate heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids are spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change. Flow through a plate heat exchanger may be parallel, cross, or counter. Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer.

By implementing the use of a plate heat exchanger, energy can be transferred between two fluids at different temperatures. This improves efficiency through heat transfer. The energy already in the system can be transferred before it leaves the system.

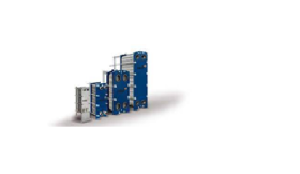

The four main types of Plate Heat Exchanger:

- Gasketed PHE

- Brazed PHE

- Welded PHE

- Semi-welded PHE

The working principle of the plate heat exchanger consistsof a closed chamber through which pipes, including pipes and other fluid paths, circulate, allowing a liquid to circulate in the other without mixing.

Advantages:

- High heat transfer rate

- Less heat loss

- Compact structure, space-saving

- Easy to change heat transfer area.

- Easy to clean and repairEasy to clean and repair.

- Wide range of application

- Long service time

The main advantages of plate-type heat exchanger are a Simple and Compact in size. Turbulent flow helps to reduce deposits which heat transfer, no extra space is required for dismantling in Plate heat exchangers. Plate type heat exchanger is Maintenance simple and can be easily cleaned.