Pipeline Components

Introduction:

At BlissFlow Systems, we specialize in supplying high-performance Pipeline Components tailored for industrial engineering applications. Serving clients across India, Singapore, Malaysia, Indonesia, UAE, Saudi Arabia, our product line is engineered for precision, durability, and reliability.

Pipeline components are essential parts of a pipeline system, designed to facilitate the safe and efficient transportation of fluids, gases, or solids from one point to another. These components work together to ensure reliable operation, minimize downtime, and prevent accidents. They are used in various industries, including oil and gas, water treatment, chemical processing, and power generation, and are critical to the functioning of modern infrastructure.

Damper

In HVAC, dampers control the flow of air. They work much like a valve that controls water flow. The damper’s blades will rotate along axles to either open or close the damper. In most dampers, these blades will be tied together with a linkage assembly so that all blades rotate at the same time. When open, air can flow through the free area between the damper’s blades. When closed, the blades will block incoming air.

Most dampers will use an actuator to control blade rotation. Actuators are attached to the driving blade axle of the damper. The damper’s linkage will translate this rotation to the other blades, so that all blades rotate together

Inline Static Mixer

A static mixer uses stationary elements within a pipe to continuously mix fluids without relying on moving mechanical parts. The process involves dividing the fluid stream, creating turbulence, and then reuniting it, achieving homogenization. The number of elements and their arrangement determine the degree of mixing achieved.

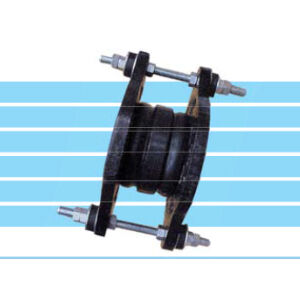

Expansion Joint

An expansion joint is a flexible connector used in pipeline systems to absorb thermal expansion and contraction, vibrations, and movements between pipes, equipment, or structures. It allows for movement in multiple directions, reducing stress and strain on the pipeline and connected components. Expansion joints help prevent damage, leaks, and failures, ensuring safe and reliable operation in various industries, including oil and gas, chemical processing, power generation, and HVAC. They come in various types, such as bellows, flanged, and rubber expansion joints, each designed for specific applications and conditions.

Our Pipeline ComponentsRange Includes:

- Damper:A damper is a device that absorbs or reduces vibrations, shocks, or oscillations in mechanical systems, reducing stress and strain, minimizing vibrations and noise, and preventing damage and fatigue. There are various types of dampers, including hydraulic, mechanical, pneumatic, viscous, and tuned mass dampers, each utilizing different mechanisms such as fluid, friction, springs, or air to absorb energy

- Vibration isolator: Vibration isolators come in various types, including spring isolators that use coil springs, rubber isolators that utilize rubber materials, and pneumatic isolators that rely on air or gas. Additionally, there are elastomeric isolators made from flexible materials like rubber or polyurethane, active isolators that employ electronic controls to cancel vibrations, and passive isolators that use mechanical components to reduce vibrations. These types of isolators cater to different applications, including industrial machinery, precision equipment, and sensitive instruments.

- Expansion Joint: Expansion joints are crucial components in various systems, and they come in different types to suit specific needs. These include bellows, flanged, rubber, metal, fabric, and gimbal expansion joints, each designed to absorb thermal expansion, vibrations, and movements in piping systems, industrial applications, and other fields. By allowing for flexibility and movement, expansion joints help reduce stress, prevent damage, and ensure the smooth operation of equipment and systems.

- Inline Static Mixer:Inline static mixers are motionless devices that blend fluids, gases, or solids in a continuous process using fixed internal elements like baffles or blades. Types include helical, fin-type, Kenics, wafer, PTFE corrosion-resistant, and S-type mixers, each designed for specific applications and industries such as oil and gas, water treatment, and process industries

Why Choose Bliss Flow Systems?

- Regional Expertise: Trusted engineering supplier across India, Singapore, Malaysia, Indonesia, UAE, and Saudi Arabia.

- Certified Quality: All products comply with international safety and performance standards.

- Industrial Compatibility: Designed for oil & gas, chemical, water treatment, and power industries.

- Timely Delivery & Support: Pan-Asia logistics and expert technical support.

FAQs:

- What industries use Pipeline Components from Bliss Flow Systems?

A. Our equipment’s are ideal for oil & gas, marine, chemical, petrochemicals, power generation, steel industries and water treatmentindustries. - Can I get customized Pipeline Components?

A. Yes, we offer custom configurations based on your operational requirements and industry standards.

- What Brand/OEM do you represent?

A.We Represent the Reputed Brand ofKoflo, Rufouz Hitechin India,Singapore, Malaysia, Indonesia, UAE, Saudi Arabia.

Looking for Pipeline Componentsin India, UAE, Singapore, Malaysia, Saudi Arabia, or Indonesia? Contact BlissFlow Systems today for expert guidance and premium solutions.

📞Request a Quote | 📩sales@blissflowsystems.com