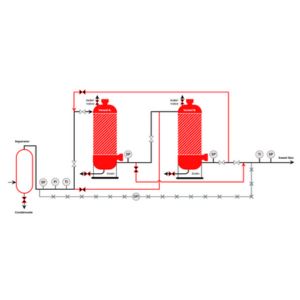

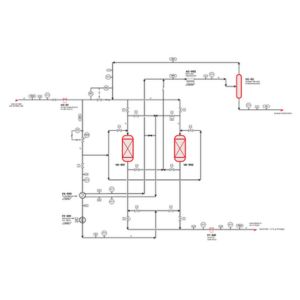

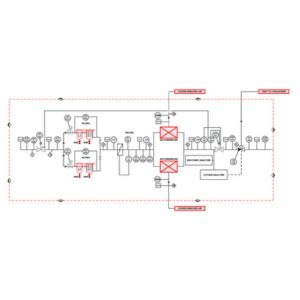

Prior to entering the amine regenerator column, the rich amine stream is preheated in the lean/rich amine heat exchanger using hot lean amine. The rich amine solution is then regenerated in the amine regenerator column, with the acid gas components being stripped out at low pressure in the amine regenerator reboiler. Downstream of the lean amine cooler, a continuous slipstream is diverted for filtration, with particulate and activated charcoal filters in place to remove solid particles from the circulating stream. The acid gas stream from the amine regenerator column undergoes cooling in the condenser and separation in the reflux separator to remove saturated water vapor and traces of solvent. The sour water separated is recirculated back into the regenerator, while the acid gases are discharged to the battery limit. The BlissFlow Amine Type Acid Gas Removal Units are equipped with interconnecting piping, valves, steelworks, instrumentation, and control systems. Depending on the specific requirements, additional conditioning facilities like cooling, separation, and filtration may be included in the acid gas removal section, along with features such as an antifoam injection system, amine drainage system, and amine make-up system in the amine regeneration section.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.