| Liquid-Liquid Coalescers are physical devices designed to enhance gravity separation of a mixture of two liquids that are immiscible, or non-soluble in one another. They do this by increasing the size of the dispersed phase droplets, thereby increasing the settling rate. The coalescing media provides surface area for interception of dispersed droplets. Droplets contact the surface, breaking the interfacial tension between the dispersed and continuous phase liquids, allowing multiple droplets to join forming very large drops or a continuous liquid film. These large drops settle by gravity, as defined by Stokes Law: | |

| The size of a gravity decanter is derived from the terminal settling velocity of a minimum sized droplet and the inertial force imparted to the droplet due to the velocity of the mixture as it flows through the vessel. All droplets larger than the minimum will settle at a higher rate. API Publication uses 150 micron droplets for oil/water systems in refineries. An effective coalescing media will increase the minimum droplet diameter, effectively reducing the required settling time, reducing vessel volume. | |

| Many different media may be used to promote droplet growth including: | |

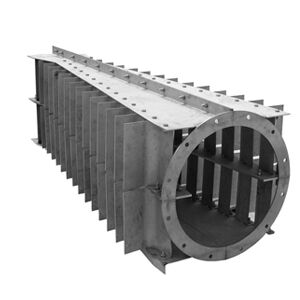

- Parallel Flat Plates, which are typically used in fouling services with solids, and liquids that are readily separated. Accumulated solids may be flushed periodically.

- Corrugated Parallel Plates, such as AMACS Plate Pak® is a refinement of the parallel flat plate concept. It is more efficient than flat plates, and can tolerate some fouling and solid loading, but not as much as the flat parallel plates.

- Stokes Pak®, is corrugated foil similar to structured packing, although we have developed styles specifically for liquid-liquid phase separation. It is higher in surface area than both flat and corrugated parallel plates, but intolerant of solids.

- Interceptor Pak® is knitted wire mesh media, often co-knit with fiberglass or Teflon yarn. We highly recommend Interceptor Pak® as an upgrade for units using Excelsior (shredded wood or hay) or Steel Wool media. Interceptor Pak® has the highest surface area available and is the most efficient coalescing media designed for long-term use. Entrained solids will foul the surface of the media, increasing pressure drop and reducing operating life. If solids are anticipated, we recommend a filtration stage or other means of solids removal immediately upstream of the Interceptor Pak.

AMACS Coalescing Media is available in a wide range of metallic alloys (ex. 304 SS, 316 SS, Monel, Alloy 20, and Hastelloy) and polymers (ex. Polypropylene, Dacron and Teflon) and Fiberglass. Our applications engineers are happy to assist you in selection of the appropriate coalescing media for your process.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.