Special :

- These thermowells are fabricated from pipe with a welded end cap.

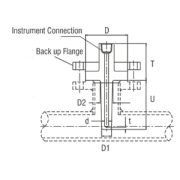

- These thermowells are installed directly into the process by using a bolted flanged connection.

- Available in various shapes like straight, straight with reduced tip, partial taper & full taper.

- All type of flanges and flange facings are available as per ansi / din /jis & bs.

- Ideal for use in longer length tank & vessels where bar stock is a limitation

Sleeved ( Lined ):

| Type | Bar-stock flanged |

|---|---|

| Well Material | SS316 |

| Process connection | Flanged 1″ (DN25) to 3″ (DN80) as per ANSI or DIN as standard. Other on request. |

| Lining Material | Hastelloy C, Nickel, Titanium, Tantalum, Silver |

| Lining thickness | 0.4 mm for Tantalum & Silver, 1 to 1.5 mm for other materials as standard. Other thicknesses can be provided on request. |

| Insertion length | To be specified |

| Note | Sometimes even the conventional stainless steel flanged thermowells can be provided with carbon steel flange corresponding to ASTMA105, with a lining of 3 mm thick stainless steel plate on the RF portion of the flange. This construction offers a very economical solution without having to surrender corrosion resistant characteristics of stainless steels for wetted parts. |

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.

Currently there are no files available for download.