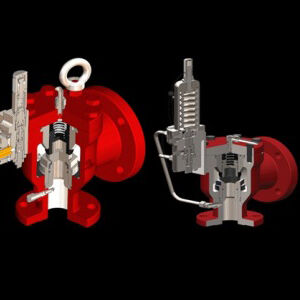

Tank Blanketing Valve

Principle of operation

Tank Blanketing Valve

The operating principle of the Tank Blanketing Valve is to maintain a positive pressure within an enclosed storage tank by introducing a gas such as nitrogen into the vapour space above the product at a required pressure.

This ‘blanket’ prevents the stored product from vaporising into the atmosphere, prevents contamination to the stored product and also helps to reduce product combustibility by eliminating oxygen-rich air.

The valve also offers primary vacuum relief for the storage tank, acting as a pressure regulator. It does this by supplying gas to the vapour space when pressure decreases within the tank to the valve’s set point.

Once the gas blanket is re-established to the required pressure the valve closes.

Standards Compliance

Elmac’s products comply with all relevant industry standards including ATEX & ISO 16852 (Flame Arresters); API 2000/ISO 28300 & NFPA30 (Venting & Storage of Combustible Vapours & Liquids) and possible BLEVE (fire engulfment) incidents. In addition, Elmac is accredited to the following international standards: ISO 9001 (Total Quality Management), ISO 14001 (Environmental Management) and OHSAS 18001 (Occupational Health & Safety).

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.