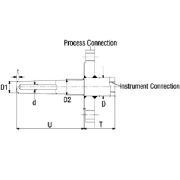

Threaded :

1).The thermowell stem shape can be straight or reduced for fast response time

2). Extension, immersion length and reduced length as well as the bar dimensions can be chosen according to process requirements

3).Different grades of surface finishing are also available

4).The process connections are threaded: ½”NPT, ¾”NPT.

5). A wide choice of standard materials is available

6).Special versions can be manufactured according to specification

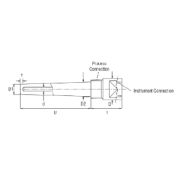

Welded:

Temperature sensors or indicating type temperature gauges are not directly inserted into the process pipe, unless these are used to measure the outside temperature of process pipe, instead, these are used with thermowells. By using thermowells, sensors and gauges will not interfere the process line operation, and the users are able toperform the maintenance procedure of the process line more easily. These thermowells can be used in a high steam line or Vapor line. These are directly welded onto the socket or pipe so can be a semipermanent. Therefore, the user must carefully deicide its material and specification before welding process is performed.

Flanged:

Temperature sensors or indicating type temperature gauges are not directly inserted into the process pipe, unless these are used to measure the outside temperature of process pipe, instead, these are used with thermowells. By using thermowells, sensors and gauges will not interfere the process line operation, and the users are able to perform the maintenance procedure of the process line more easily. These types are most common bar type, and these are installed onto the process line by attaching a flange. It is useful in the process line where a high pressure and a fast current exist. A623 is manufactured with a Full Penetration welding procedure so can be used in a high pressure gas line.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.