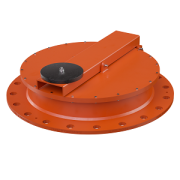

Emergency Relief Vents

Principle of operation

Emergency Relief Vents are fitted to storage tanks to allow emergency flow due to the excessive venting requirement from a fire burning around a storage tank. This eliminates a costly tank rupture, providing emergency venting from abnormal internal pressure beyond the capability of the pressure relief vent. In the event of a fire, the pallet will lift at a pre-determined pressure, thus creating a large venting area.

A PTFE insert is provided to achieve leak tight sealing between the pallet and seat under normal operating conditions. An alternative model is available, fitted with an additional spring-loaded vacuum valve that will open under negative pressure to protect the tank from any damage that may occur under vacuum conditions.

Standards Compliance

Elmac’s products comply with all relevant industry standards including ATEX & ISO 16852 (Flame Arresters); API 2000/ISO 28300 & NFPA30 (Venting & Storage of Combustible Vapours & Liquids) and possible BLEVE (fire engulfment) incidents. In addition, Elmac is accredited to the following international standards: ISO 9001 (Total Quality Management), ISO 14001 (Environmental Management) and OHSAS 18001 (Occupational Health & Safety).

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.