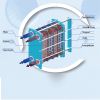

Plate and Frame Heat Exchanger (Gasketed)

We can provide GPFE’s with our own plate configurations and designs or provide units with many of the plate designs already available in market today, allowing us to meet a customer’s specific needs or replace existing units.

The primary component of DESCO GPHE’s is the heat transfer plates formed from thin sheets of corrosion resistant metal, primarily stainless steel or titanium. These sheets are press formed into the required corrugated or embossed pattern. The plates are compressed and sealed with a selected synthetic rubber between a fixed and movable frame. The plates are suspended, supported and aligned using upper and lower guide bars. The plates are compressed using tightening bolts and nuts. In this design, plates can be added or removed as the heat duty dictates.

The pattern on the plates when sealed form channels for the hot and cold fluids to flow. The fluids flow counter currently providing for optimum heat transfer efficiency. DESCO GPHE’s can handle very close approach temperatures and are capable of providing an over-all heat transfer co-efficient (U-value) significantly better than traditional heat exchangers. This is due to the units high turbulent flow resulting from the corrugated patterns of our plates.

DESCO GPHE’s can meet a wide range of heat transfer application requirements using precise plate selections from an array of high and low NTU plate configurations. Among the variables we take into account, when considering an optimum selection for our customers are flow rate, design pressure, pressure drop, material compatibility and the specified heat transfer duty.

gasketed-plate2

There are many advantages to our GPHE’s. They can be easily opened for inspection and maintenance. Also, the lightweight and compact footprint saves installation space and disassembly space when compared to a traditional shell & tube exchanger. The GPHE’s can be easily cleaned within the footprint of the unit and without tube cleaning.

With DESCO’s vast experience in heat transfer and design engineering, we are capable of putting together small heat exchanger packages or “skids” complete ancillary piping, valves, pumps and controllers.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.

Currently there are no files available for download.