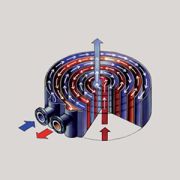

Spiral Heat Exchanger

The design consists of two (2) strips of metal, separated by spacer studs wound around a core, creating two (2) flow passages. The cross-section of the flow passages are controlled by the stud height and the width of the strip.

The relatively large flow channels yield low pressure drops. However, the concentric nature of the flow passages, combined with interruptions by the spacer studs, yields turbulent flows even at low Reynolds numbers, increasing heat transfer and reducing fouling.

The units can operate in a cross or counter current flow pattern, and can handle viscous liquids, slurries and sludges with up to 45% suspended solids.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.

Currently there are no files available for download.