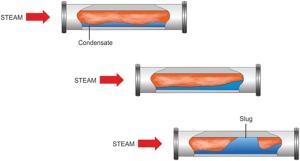

A Steam Trap is an integral part of a steam system. Steam traps play an important role in maintaining the productivity and efficiency of the steam system. This exhaustive guide answers all the questions one might have about steam traps, their working principles, troubleshooting, etc. Steam traps an automatic drain valve which distinguishes between steam and condensate.

A steam trap holds back steam & discharges condensate under varying pressures or loads. The steam traps should have a good capacity to vent out air and other non-condensable gases quickly while holding back the live steam.

Working Principle:

Energy is getting more important day by day. According to the diminishing of energy sources all the industry sectors searching for alternative sources for increasing productivity. In this case, steam which is one of the energy carriers is also getting more important. Trapping of steam and using more heat of steam is up to choosing the right steam traps. Although steam traps look simple and small their obligation is very complex. Saving more energy is related to the right chosen steam trap type and size. Working principles should be known well for choosing the right steam trap for the process.

Types

Mechanical Trap: This range of steam traps operates by sensing the difference in density between steam and condensate. Sub Groups are Bucket type, Open bucket, Inverted bucket with lever, without lever Float type, Float with lever, Free float

Thermodynamic Trap: This range of steam traps operates by sensing a difference in thermodynamic properties between steam and condensate. Thermodynamic steam traps rely on the fact that hot condensate, released under dynamic pressure, will flash off to give a mixture of steam and water. Sub Groups are Disc type Impulse type Labyrinth type Orifice type

Thermostatic Trap: This range of steam traps operates by sensing a difference in temperature between steam and condensate. Sub Groups are Bimetallic-type Metal expansion types

Advantages

Efficient steam trapping will result in optimum efficiency and will achieve the following:

- Fast heat-up of heat transfer equipment

- Maximum equipment temperature for enhanced steam heat transfer

- Maximum equipment capacity

- Maximum fuel economy

- Reduced labor per unit of output

- Minimum maintenance and a long trouble-free service life