Orifice Plates

Design : Conforms to ISA RP 3.2, DIN 1952 , BS 1042, ISO-5167

Types : Square edge concentric, Quadrant edged, conical entrance, Eccentric, Segmental, Conditioning Orifice Plate, Multistage Orifice Plate Assembly.

Plate material : SS 304, SS316, SS316L as standard. Hastelloy-C , Monel , PP , PVC , PTFE coated , etc. can be given on request.

Orifice Bore : In accordance with ISO-5167, BS-1042, ASME MFC 3M, R.W.Miller, L.K.Spink, AGA-3

Tab : In the same material as plate & is welded to orifice plate. Tab plate integral to the Orifice plate (i.e. without welding) can also be offered as a special case.

Vent/ Drain : Vent or Drain holes are provided as per customer’s requirement. The diameter of the vent or drain holes are as per ISA RP 3.2

Flange Union : Weld neck, Slip on, Threaded, Socket welded with RF or RTJ facing Orifice flanges are in accordance with ANSI B16.36 with minimum flange rating of 300# for sizes up to 8″ or male – female flanges in accordance with ANSI B16.5.

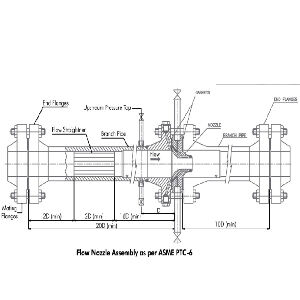

Specifications- Orifice Plate assembly

Refer by downloading the attachment

Specifications- Orifice Plate Assemblies with RTJ Holder

Orifice plate is screwed to the plate holder. Generally the plate holder is of soft iron material. The Orifice plate is available in standard material such as SS316, SS304, SS316L, Monel, Hastelloy-C, etc. Other materials are available on request. The plate holder along with the orifice plate can be also machined from one piece.

RTJ holder material is selected so that the RTJ holder hardness is less than that of flange hardness.

Specifications- Restriction Orifice

While single restriction orifices are often sufficient to meet the situations where limitations arise due to process conditions orifices unacceptable. In such situations, use of multiple solution.

The foremost consideration for the case of multiple restriction is applies whether or not the fluid is liquid or vapour/gas. Higher velocities resulting in vibration and noise problems. The other consideration is not just about maximum permitted particularly for gas flow. If the process condition indicates that the use of single restriction plate, care should be exercised to the critical pressure drop. Critical implies a pressure drop 50 percent of the absolute upstream pressure at which point Construction of Multistage Orifice Assembly comprises of plates separated by a distance of one pipe diameter and in between them. End connection is either suitable for butt flanges.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.