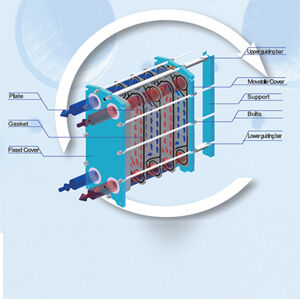

Standard Heat Exchanger

- BEM Model TEMA Class C.

- Design Pressure: 8 kg/cm ²

- Design Temperature: 250°C

- Number of Tube side passes: 1, 2 & 4

- Tube Diameter: 19.05 mm x 1.6 mm thk (Seamless & welded option )

- MOC: SS 304/SS 316/Hastelloy options available.

- Nozzle sizes can be provided as per process requirement.

- Expansion bellow can be provided as per design requirement.

- Available with Vertical or Horizontal orientation.

Below listed are the related files that can be downloaded to you PC. All the files are in PDF format.

Currently there are no files available for download.